I am amazed at how fast time flies when you’re having fun – the DoTheDaniel.com team has already had such an amazing 2016 and there are so many more adventures in store around the world. As 2015 drew to an end, we had the opportunity to sit down to dinner with Ford Canada to learn about what one of our favourite brands is doing when it comes to sustainability and environmental practices. We were left feeling extremely impressed with the innovations they are taking on the road to a better world and are excited to finally tell you about them.

#FordFarmToCar is a hashtag that I encourage you all to follow to see why we are feeling so impressed with the team at Ford Canada. The following video can help to provide a little bit of context:

At Actinolite Restaurant in Toronto, a sustainable leader in the culinary world, we sat down to a dinner that mirrored the innovation of Ford Canada in many of their vehicles already on the road. I had no idea that so many environmental changes had already been put into practice. Unfortunately, when it comes to the automotive industry, many companies don’t understand the long term positive effects of changes such as the ones Ford Canada has made.

All automobile companies should follow suit in using more sustainable materials when it comes to designing a new vehicle. Some companies may even decide to use something like urethane foam in their components to help make it stronger and durable, as well as making a difference to your fuel savings. This could be the way of the future, and Ford Canada have already started to make changes.

Here are just a few of the changes made that are helping to change the automotive industry for the better as we all work towards a healthier way of thinking.

“What goes into a vehicle at the beginning of its lifecycle and what comes out of it at the end of production contributes greatly to its environmental friendliness. Food by-products, oversupply and other biomaterials are getting a second life in Ford vehicles.”

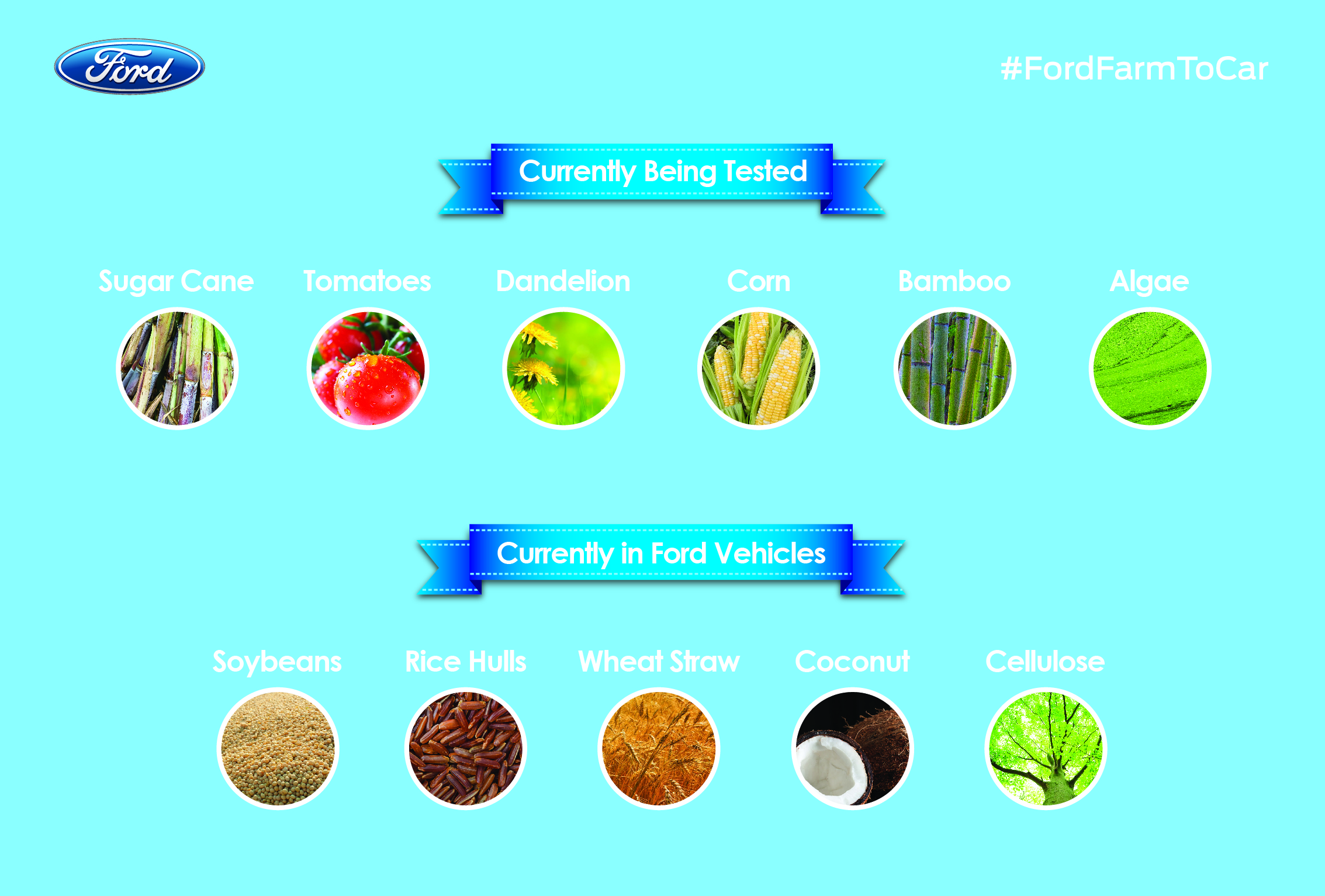

Currently in Ford Vehicles (as provided to us by Ford Canada)

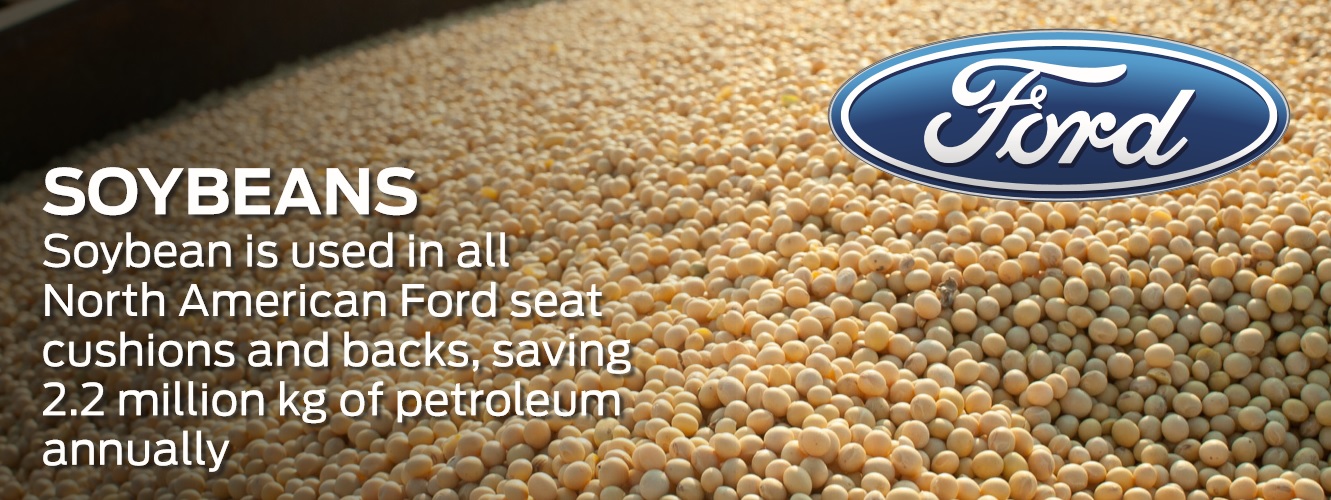

It all started in the 1940s when Henry Ford built a plastic paneled car using soy – and had a soy suit to go with it!

Since 2011, all Ford vehicles built in North America have soy foam in their seat cushions and backs. This saves an estimated 2.3 million kilograms of petroleum per year. In addition, 85 per cent of headrests produced in North America and the headliner on the Ford Escape use soy foam. Ford continues to investigate new applications for soy foam, such as for underhood and energy-absorbing foams.

Ford uses renewable, natural-fibre materials to reinforce plastic and for other applications in vehicles. In 2014, Ford introduced a new composite plastic material reinforced with rice hulls (by-product of rice grains) in the wire harness of the comfortable Ford F-150.

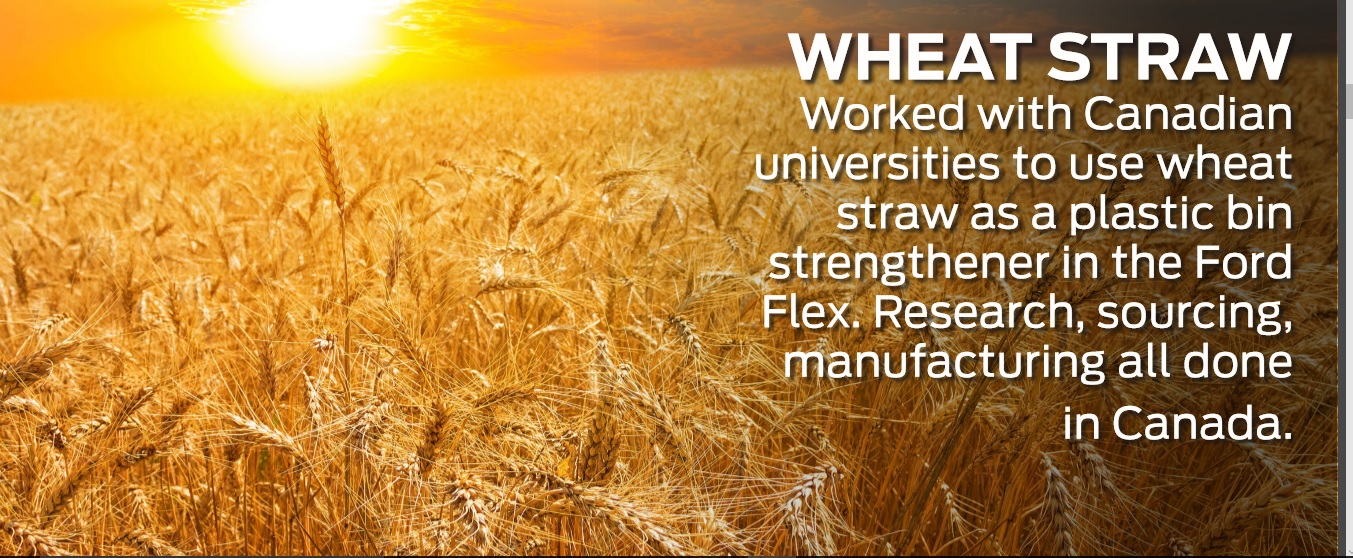

Wheat straw-reinforced plastic is used in the storage bins of the Ford Flex – the world’s first application of this material. The use of wheat straw-reinforced plastics in the Flex reduces our petroleum usage by some 9,000 kilograms and our CO2 emissions by about 13,600 kilograms annually.

Coconut Coconut coir, made from coconut husks, is used in the trunk mats of some vehicles, including the Ford Focus Electric.

In 2014, Ford launched an industry-first application of cellulose-reinforced plastic in the Lincoln MKX. This material is being used to replace fibreglass reinforcement in the centre console. The cellulose fibres in this composite come from sustainably grown and harvested trees and related byproducts. The material reduces weight by approximately 6 per cent. It also has a smaller carbon footprint than the glass-fibre-reinforced plastic it replaces, in part because it takes less time and energy to mold cellulosereinforced parts than traditional glass-fibre-reinforced plastics.

Currently Being Tested

Sugar cane–based plastic has been made into interior fabrics and is being tested for durability and performance.

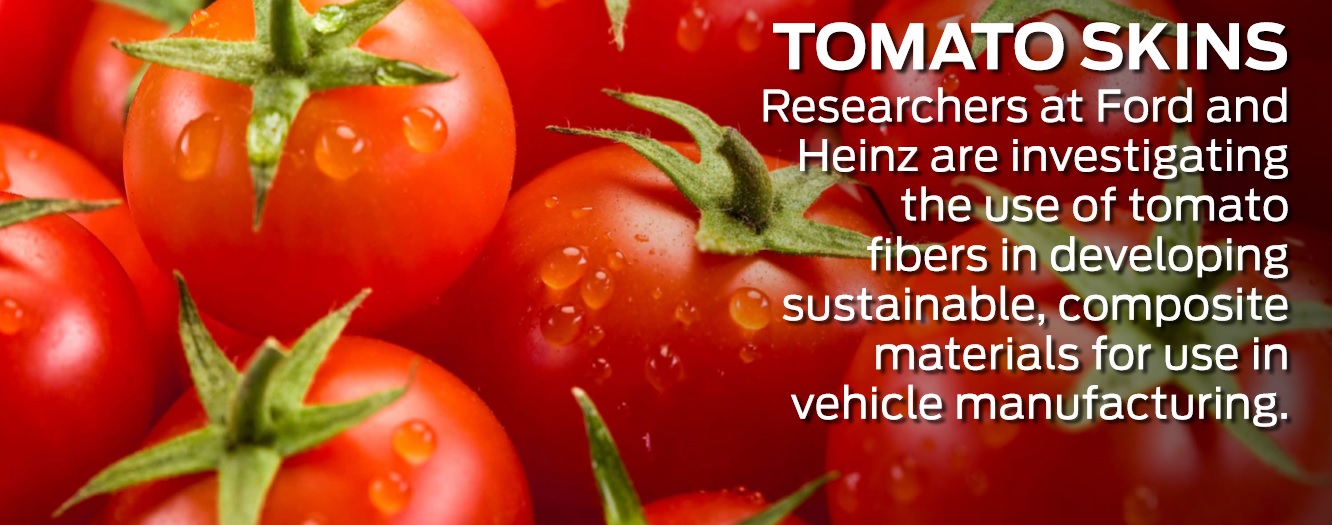

Ford is collaborating with the H.J. Heinz Company to explore using tomato fibre, a byproduct of ketchup production, to develop a more sustainable bio-plastic material for our vehicles. Ford researchers are testing the material’s durability for potential use in vehicle wiring brackets and storage bins.

Agricultural corn by-product can be processed into plastic parts, fabrics, fibres or films. Ford is currently testing the product for potential uses in carpeting, upholstery and interior trim.

Bamboo is a fast-growing grass-up to 4 cm per hour!-that is being researched for potential uses in veneers and as filler material.

Algae is a promising sustainable material being researched by Ford. It grows very quickly, replicating up to four times per hour, and has a high per acre yield when compared to other crops.

For those of you who understand environmental change, you’ll know how incredible these endeavours truly are. And if this is the first time you’re reading about the changes made to Ford Canada, I hope you understand what it all means for the industry. Truly, and pardon me for repeating myself, they are on the road to real change. I could not be more proud to support and drive Ford vehicles now that I know all of this.

A photo posted by Julio Reyes (@fashionights) on

To see the latest and greatest vehicles in the Ford Canada family, make sure to head to www.ford.ca and check to see where your local Ford dealership is by clicking here.

Amazing vehicles, innovation and inspiration are all available if you follow @FordCanada on Instagram & Twitter. Use the #FordFarmToCar hashtag to join in on the social media conversation around environmental change and sustainability in the automotive industry. We’d love to hear what you have to say!

For more behind the scenes of this and other amazing brands and events we are working with, make sure to follow along with the #DoTheDaniel Instagram account. We’d love to have you join us on our adventures around the world!

Photos: Ford Canada & Daniel Reyes

Cheers!